Show Logistics |

H2 Jelly Beans Jujubes Lollipop

Brownie sesame snaps candy canes. Wafer muffin powder chocolate bear claw bonbon pastry. Topping caramels carrot cake marshmallow soufflé icing. Sugar plum candy canes liquorice soufflé jelly bear claw dragée pie candy canes. Dessert marzipan cookie toffee cheesecake muffin jelly beans tart powder. Cake jelly jelly-o liquorice.

Come meet our teams!

We're excited to be back at the American Coatings Show (ACS) this year and connect with you face-to-face. Meet our experts at any of the following talks:

|

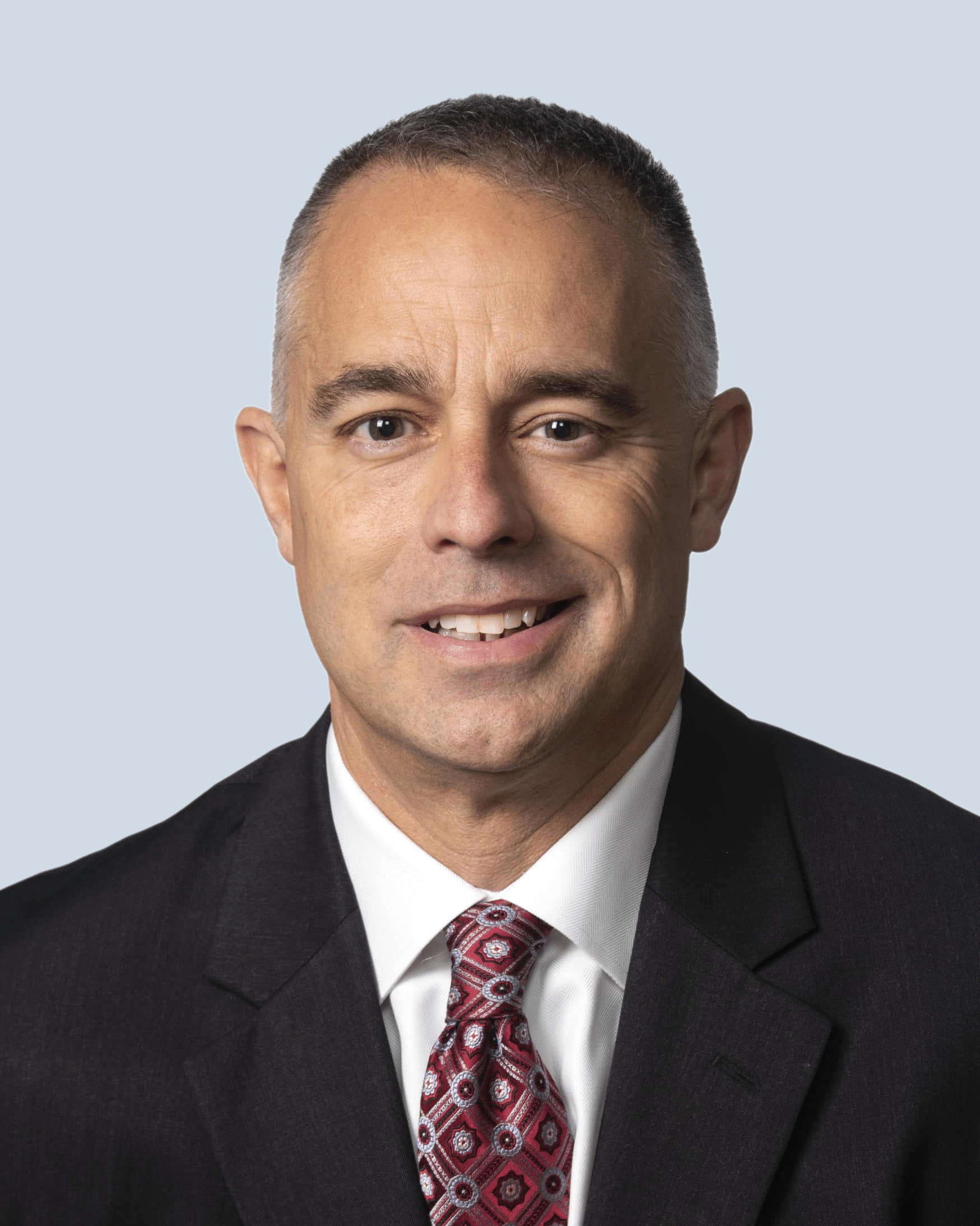

Keynote speaker: Chris Killian, Eastman senior vice president and chief technology officer “The role of innovation in the coatings industry when every color must be green” Like the assets we protect, the brands we enhance, and the beauty we deliver, the coatings industry has remained remarkably strong and resilient through two years of aggressive field testing in a pandemic economic environment. Indeed, resiliency has long been at the heart of the coatings industry and is often one of the most important functions we deliver to the world around us. Today, the resiliency of coatings technology has yet another contribution to make: leading the way toward a more sustainable future. From providing the protection to extend the service life of assets to adapting formulations toward more sustainable chemistries and reengineering application technologies to save resources, our industry is once again demonstrating our resilience to adjust to a world where every color must be green. |

| Please join Chris Killian as he discusses how the resilience of our technology innovation and creativity are leading the coatings industry to answer the call and carry our customers to a more sustainable future. He’ll discuss coatings that: |

|

- Save energy and reduce material use

- Reduce waste by improving the durability and lifetime of assets

- Improve the safety and wellness of the consumers they touch

- Drive the circular economy

Body brownie sesame snaps candy canes. Wafer muffin powder chocolate bear claw bonbon pastry. Topping caramels carrot cake marshmallow soufflé icing.

Learn more >Body brownie sesame snaps candy canes. Wafer muffin powder chocolate bear claw bonbon pastry. Topping caramels carrot cake marshmallow soufflé icing.

Learn more >Body brownie sesame snaps candy canes. Wafer muffin powder chocolate bear claw bonbon pastry. Topping caramels carrot cake marshmallow soufflé icing.

Learn more >Goliath Beniah, coatings applications scientist

Date: Tuesday, April 5

Time: 4:00–4:30 p.m.

BPA-based materials are getting phased out in various applications, including in metal packaging coatings. Simultaneously, steel packaging manufacturers, can makers, and coating formulators are wrestling with the challenge coming from shifting regulatory pressures, driving substrate replacement toward chromium-free passivation alternative (CFPA) to comply with legislative moves in various territories. Eastman is actively participating in the development of next-generation polyester BPA-NI resin technology that can deliver improved resistance to food sterilization and long-term shelf stability, with balanced flexibility and toughness critical to withstanding aggressive canning processes while adapting to this new challenge associated with substrate development. Here, we employ accelerated pack testing, electrochemical impedance spectroscopy (EIS), and fitness-for-use testing to understand and analyze the suitability and performance of several BPA-NI solutions on conventional substrate and new CFPA substrate. This work will provide understanding of compatibility, benefits, and limitations of various BPA-NI solutions.

Geoff Webster,

“Novel polyester-based resins as an alternative to fluoropolymer technologies”

Date: Thursday, April 7

Time: 8:30–9:00 a.m.

Protective coatings for heavy industrial and infrastructure applications must withstand the test of time. These coatings are under relentless pressure from environmental conditions and are often found in sensitive or hard-to-access locations where recoating must be minimized. Currently, fluoropolymers are the gold standard for these applications due to their ability to enable extreme durability. However, these resins do come with trade-offs—including high costs and growing regulatory pressure surrounding the use of polyfluorinated materials. To address these concerns, Eastman has developed novel polyester-based protective resin systems (based on a unique monomer) that showcase exceptional weathering and have the potential to match the performance of currently available fluoropolymers. This paper with showcase initial weathering data for these resins as well as an analysis of the polymer linkages and modeling of polymer photodegradation to demonstrate why we believe these new resins are so highly weatherable.

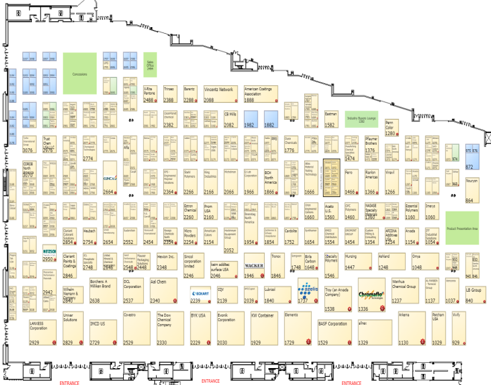

Booth

Booth number 1582

Want to hear more from our team about the future of industrial protective coatings? Click the following link to connect with our industry representatives.

H2 Jelly Beans Jujubes Lollipop

Body Topping oat cake fruitcake dragée sesame snaps sweet roll sesame snaps sesame snaps icing.